Global Shutter Technology

Pregius™ / Pregius S™

- Home

- Technology

- Image Sensor for Industrial Use

- Global Shutter Technology Pregius / Pregius S

Overview

Pregius is a global shutter pixel technology for active pixel CMOS image sensors that adopts Sony Semiconductor Solutions Corporation’s low-noise CCD structure to realize high-quality images. This technology has been named Pregius to represent the combination (Precision GS) of the low-noise performance of CCD with the high-speed and high-precision performance (Precision) of global shutter (GS) required by FA applications.

In a further advancement of Pregius, the newly developed Pregius S technology adopts a back-illuminated structure to simultaneously realize a smaller image sensor and a faster frame rate, while still maintaining the high imaging performance of Pregius. In addition, the adoption of a stacked structure has secured a large surface area for the signal processing circuits, so it has become possible to equip it with various new functions*1

Pregius/Pregius S and their logos are registered trademarks or otherwise trademarks of Sony Group Corporation or its affiliates.

*1) Find out about the new functions on Pregius S.

Technical Features

Global shutter and rolling shutter

There are broadly two types of CMOS image sensors. One uses rolling shutters that capture images by line-sequential scanning, and the other adopts global shutters that take images in the focal plane in one shot. While the rolling shutter causes distortion in the images of fast-moving objects, the global shutter is able to capture a high-speed moving image without focal plane distortion by capturing the entire object before output. It is also easy to synchronize with flash in, for example, machine vision inspection processes, enabling to improve the takt time.

Comparison between global and rolling shutters

Global shutter

Rolling shutter

In the image shot using the global shutter, the texts are legible, and the object shape is undistorted.

High-speed signal processing and high image quality

High-speed signal processing and high image quality are some of Pregius’ advantages. Pregius enables high-speed, high-precision machine vision inspection in a production line, significantly enhancing the productivity. Additional features, such as recording only specified areas in an image, help to make image inspection more efficient, further enhancing the efficiency of production lines.

Comparison between Pregius and conventional products

See the video from 00:51 for a comparison between the Pregius global shutter and a conventional rolling shutter (regarding image distortion for a moving object), and from 01:18 for a comparison between Pregius and a conventional product (regarding the amount of noise).

High-speed signal processing and low noise in one image sensor

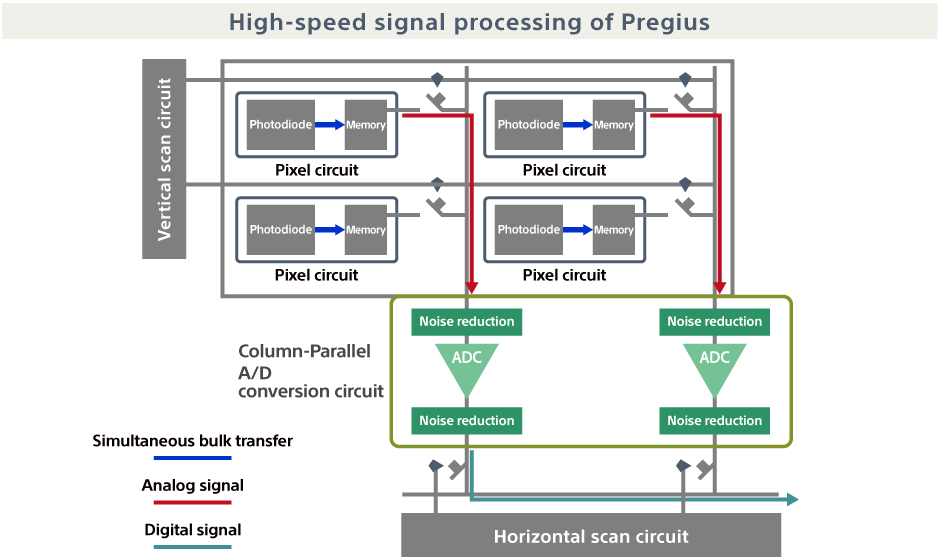

Pregius comprises a light receiving section (photodiode) with the excellent low-noise property of CCD and a memory section. The light simultaneously sensed by each photodiode of all pixels is converted to digital signal and transferred to their respective memory sections before processed. By processing the simultaneous digital signals all at once, the resulting image has no distortion. It thus offers an ideal functionality for moving object inspection.

The key to the high speed of CMOS image sensors with Pregius technology is the parallel processing. The CMOS image sensors are equipped with A/D conversion circuits, which transform the analog signal from the pixel to a digital signal. An array of several thousands of these circuits arranged horizontally realizes the high-speed processing by operating simultaneously. In the A/D conversion circuit, the analog circuit that causes noise has been changed to a different configuration so that it automatically suppresses noise. In this way, the technology both realizes the high speed and low noise in one image sensor.

Pregius S Technology

The Pregius S technology is an advanced form of Pregius technology explained above. In the Pregius S technology, the adoption of the back-illuminated structure makes it possible to achieve a faster frame rate, and the employment of the stacked structure realizes miniaturization, installation of various functions, and expansion of functions of the image sensors.

Pregius S(Global shutter technology)

Advantages of the back-illuminated structure and stacked structure(Pregius S)

The first merit of a back-illuminated structure is that it allows a wider incident angle, as illustrated below. Normally, the issues for a structure like this include measures for noise suppression and dark current. On Pregius S, we newly developed an original photodiode structure and light-shielding structure that were optimized for the back-illuminated structure. These greatly improved the sensitivity and saturation properties while also suppressing the noise generation. By utilizing these properties, it is also possible to maintain the image quality while achieving the miniaturization of pixels, which makes a more compact image sensor possible.

Futhermore, by adopting a stacked structure that overlays the pixel section and the signal processing section (see figure on the right), we succeeded in simultaneously achieving both a smaller sensor size and more functions as a result of the expanded signal processing circuit area.

Pregius S technology continues to evolve, including the use of a stacked structure that allows for wider and more efficient use of the photodiode area. Discover the details.

Functionalities of images sensors with Pregius S technology

Function introduction:

Tracking ROI, Motion Detection, Dual ADC

Tracking ROI:

When an object, like a barcode on a conveyor belt, enters into the pre-defined ROI(Region of Interest), tracking starts and the images are taken. This reduces the load of data processing to the back processor.

Models with this function:

IMX535, IMX536, IMX537, IMX545, IMX546, IMX547, IMX565, IMX566, IMX567

Motion Detection:

The sensor outputs images only when it detects motion. This reduces the processing time and the power consumption.

Models with this function:

IMX535, IMX536, IMX537

Dual ADC (Analog Digital Converter):

Two images with high and low gains are shot in parallel and combined within the sensor. The improved visibility contributes to the improvement of recognition in inspection and reduces the total inspection time.

Models with this function:

IMX530, IMX531, IMX532, IMX535, IMX536, IMX537, IMX487

Function introduction:

Fast AE、Quad HDR、Quad Shutter Control

Fast AE (Auto Exposure)

Fast AE enables rapid calculation of the optimal exposure time by capturing an image with thinned-out resolution an instant before shooting. This function makes it possible to always shoot at the optimal exposure time, even amid changes in the lighting environment or distance from the subject.

Models with this function:

IMX900

Quad HDR (High Dynamic Range)

Setting the exposure time separately for each of the four 2-by-2 pixel units makes it possible to shoot under a variety of exposure conditions simultaneously, including short and long exposure, enabling a wider dynamic range. This is extremely effective when photographing materials with different reflectivities, such as metal parts and rubber materials.

* An HDR compositing function is not included, so compositing is required at a later stage.

Models with this function:

IMX900-AMR (Monochrome)

Quad Shutter Control

Users can set the shutter timing and exposure time separately for each of the four 2-by-2 pixel units. Each individually set pixel is treated as a group of four and shot at staggered times, enabling ultra-high-speed photography of these four images.

Models with this function:

IMX900

Applications

Barcode recognition

In the logistics industry, the sorting process is automated using barcode identification, and there are demands for improved accuracy and higher speeds. Global shutter image sensors are appropriate for this sector as they can capture distortion-free images of barcodes moving at high speeds. Recently, as the increase of two-dimensional barcodes pushes up the demands for small-sized high-resolution image sensors, Sony’s image sensors with miniaturization technology are adopted more.

Of these, the IMX900, which uses 2.25 µm pixels, has a compact optical size that is compatible with the S-mount (M12) yet achieves high resolution, making it suitable for barcode reading where miniaturization and speed increase are essential.

Related sectors

FPD flaw inspection

Image sensors are used in Front Panel Display (FPD) manufacturing plants to detect abnormalities and defects on the panel surfaces and wiring patterns. With the high image quality, high resolution and high-speed shooting capabilities, the global shutter image sensors are suitable to make the processes more efficient and accurate.

Related sectors

License plate recognition

To identify license plates on vehicles traveling at high speeds, global shutter image sensors with high-speed read-out capabilities are suitable. Above all, to cover multiple lanes to monitor multiple types of cars, high-resolution image sensors are recommended.

Related sectors

Traffic and Transportation (ITS)

Imaging license plates on multiple lanes at a time

The high resolution sensors make it possible to image the license plates on multiple vehicles in multiple lanes with one sensor. We have a large product lineup from compact sensors to high resolution sensors, to suit the number of lanes. (Simulation image)

Shape recognition

Image sensors are sometimes used in recycling sites to sort the shapes of bottles and cans. The global shutter image sensors contribute to improvement of accuracy and reduction of time, since they can capture images of objects moving even at high speed without distortion.

Related sectors

Bridge examination

Bridge examinations are the inspections necessary to ensure the maintenance of bridges in a good condition. As one method of such inspections, there are increasing demands for systems that combine highly mobile drones with cameras. Compared with the examination by employees, it is not necessary to construct scaffolding and the examination can be completed by a small number of personnel, in a short period of time, and safely. The global shutter image sensors are highly expected for this application as they are capable of shooting images even under vibrated conditions.

Related sectors

Related Products & Solutions

-

Image Sensor

Global Shutter Image Sensor

Find out more about global shutter image sensors

-

Image Sensor

Ultraviolet (UV) Image Sensor

This technology is also used in UV image sensors. The product information is here.

-

Image Sensor

SWIR Image Sensor

This technology is also used in SWIR image sensors. The product information is here.

-

Image Sensor

Polarization Image Sensor

This technology is also used in polarization image sensors. The product information is here.

Related Links

About the Pregius/Pregius S logo

The Pregius and Pregius S logos may be used by clients under the following conditions and provided that prior consent is given by the Sony Group. The logo image data is provided upon signing the logo licensing agreement. Please inquire from “Contact us” below.

Eligible products : Customers' products incorporating Sony’s CMOS image sensors equipped with Pregius/Pregius S technology.

Applicable media : Outer packaging of the eligible product, catalog, poster, promotional materials such as product information webpages, other medium created for exhibitions, etc. (e.g., information panels)

The logos may not be applied to the product itself or its system (including the digital app screens).

The logo licensing agreement is subject to preliminary assessments. The assessment results will not be made public.

The license may not be granted in some cases.

Sony Group is not held liable for any damage caused in relation to the use of the logos.

Product & Service Inquiries

Click here to request for a datasheet/quotation (RFQ)!

* This button will redirect you to the salesforce.com Co., Ltd. website,

which we have entrusted.

E-mail Newsletters

Find the latest information on our newsletter for industrial and security applications.